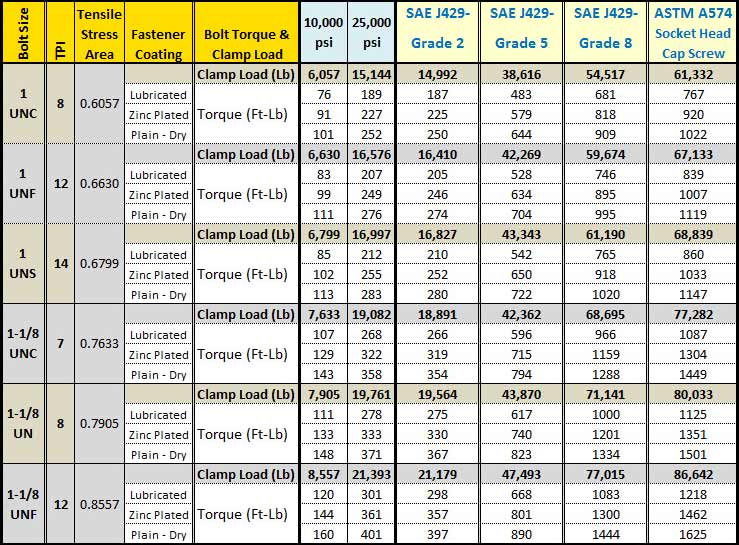

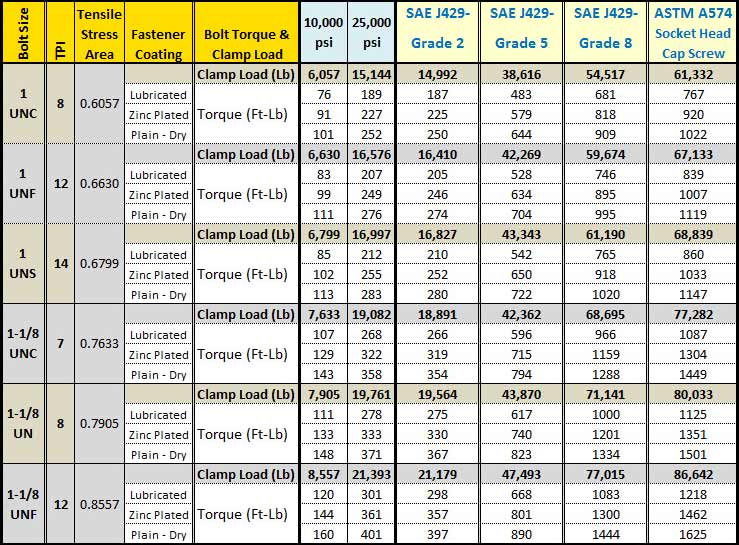

4 40 Torque Spec Suggested Maximum Torquing Values a guide based upon actual lab testing on dry or near dry fasteners wiped clean While Fastenal has used reliable sources and testing to determine

When working with 4 40 socket head screws in machinery it is recommended to aim for a torque setting between 65 70 of the failure torque rate This value will depend on There are many varying factors which affect torque The figures in this chart are safe figures for standard torque applications only The chart below can be used to convert foot pounds to

4 40 Torque Spec

4 40 Torque Spec

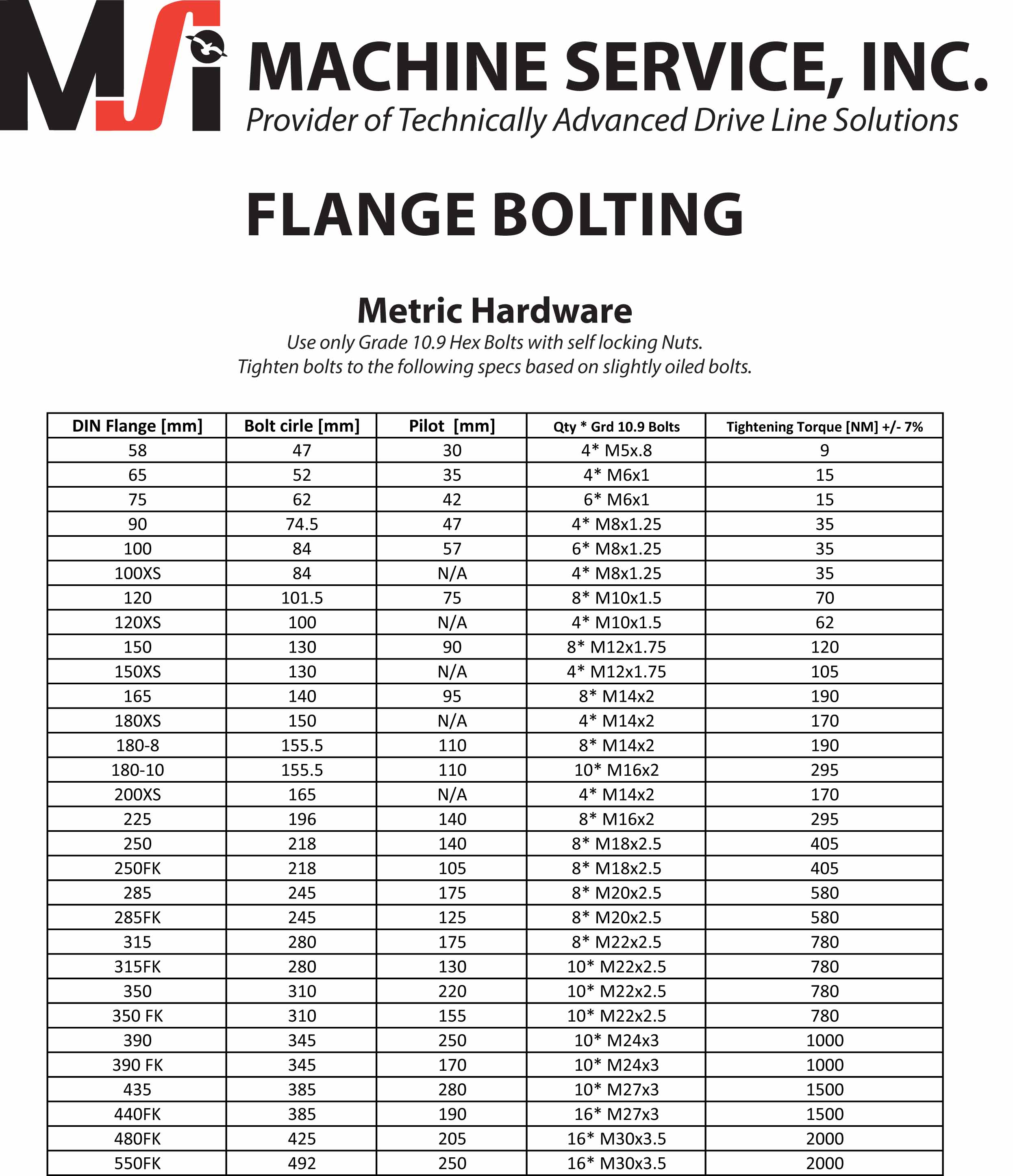

http://machineservice.com/wp-content/uploads/2015/12/Flange-Bolting.jpg

Standard Bolt Torque Chart Wordacross

https://i.stack.imgur.com/AbYnz.jpg

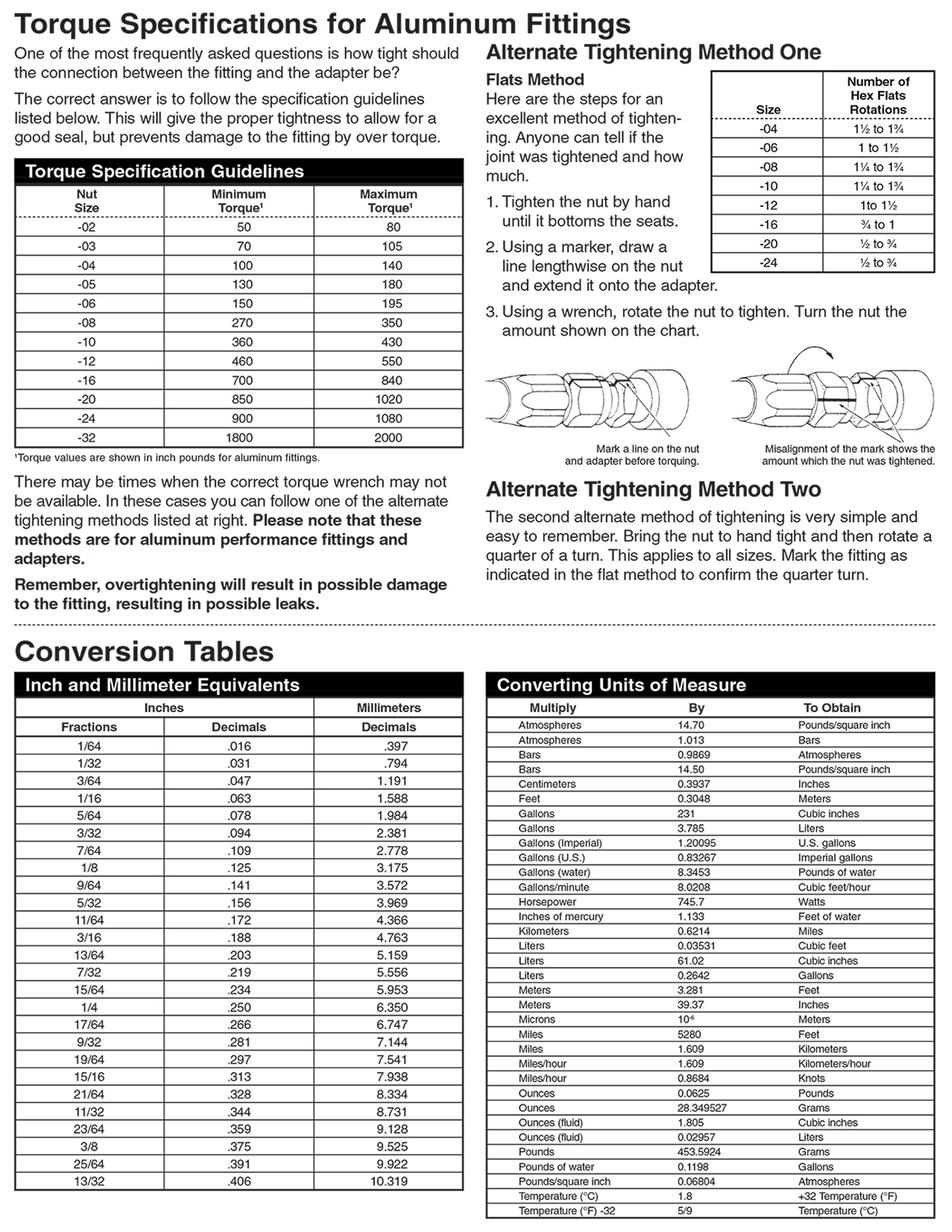

Metric Port Fittings ED Seal Tightening Torque Spec ISO 49 OFF

https://www.anplumbing.com/media/wysiwyg/Torqspecalum_1.jpg

SAE J82 has two machine screw strength levels Grade 60M and Grade 120M The Grade 60M indicates a minimum tensile strength of 60 000 P S I the 120M indicates 120 000 P S I Every application needs to be evaluated on its onwn to determine the optimum torque for each application We Ship Satisfaction Not Just Products Look to us for everything from Custom

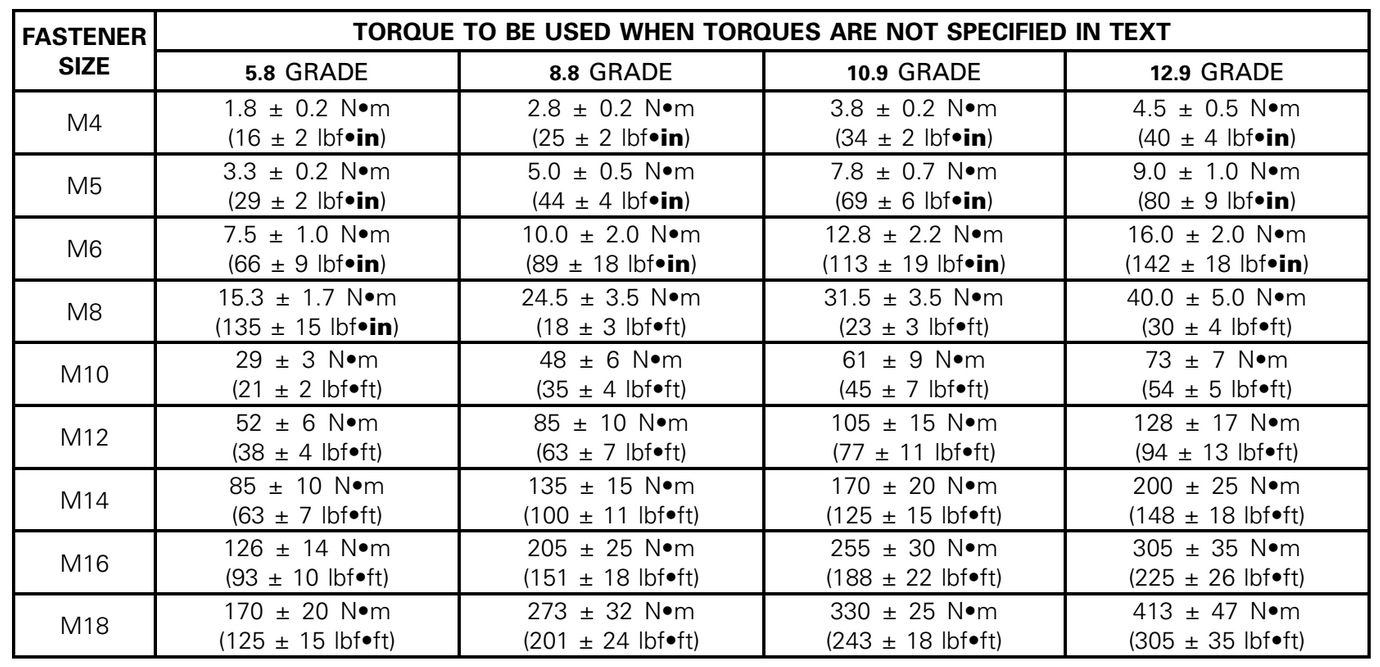

Every application needs to be evaluated on its own to determine the optimum torque for each application Grade 2 5 and 8 values are for plated bolts

More picture related to 4 40 Torque Spec

Torque Data Chart PDF 44 OFF Americanprime br

https://res.cloudinary.com/engineering-com/image/upload/v1609202871/tips/Screenshot_20201228-174257_Adobe_Acrobat_awclan.jpg

Head Bolt Torque Hot Sex Picture

https://www.extreme-bolt.com/images/Applications/Torque/A286-Torque-Spec.gif

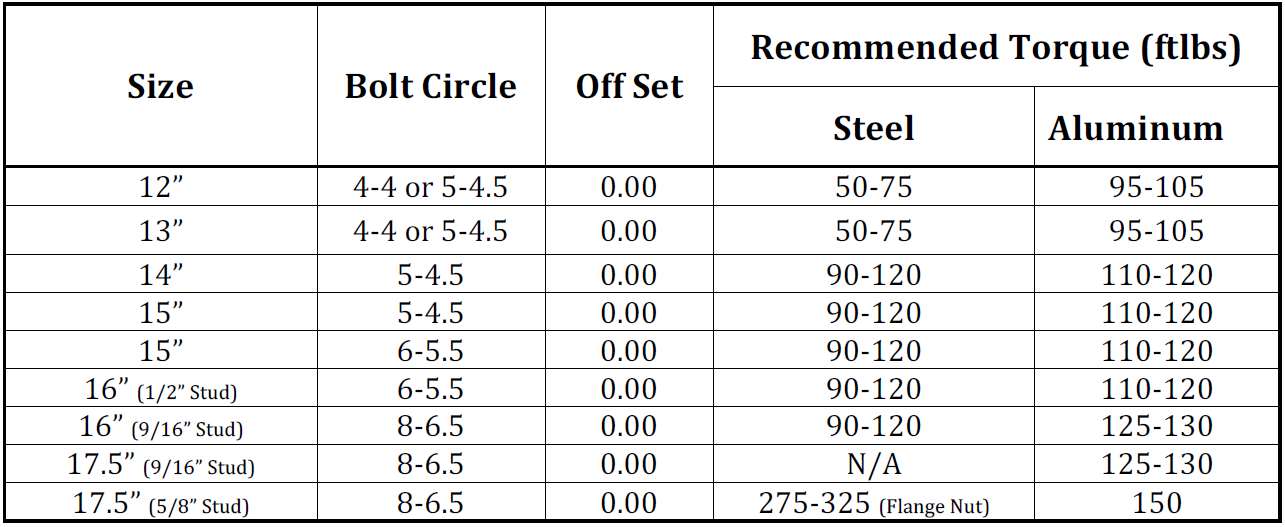

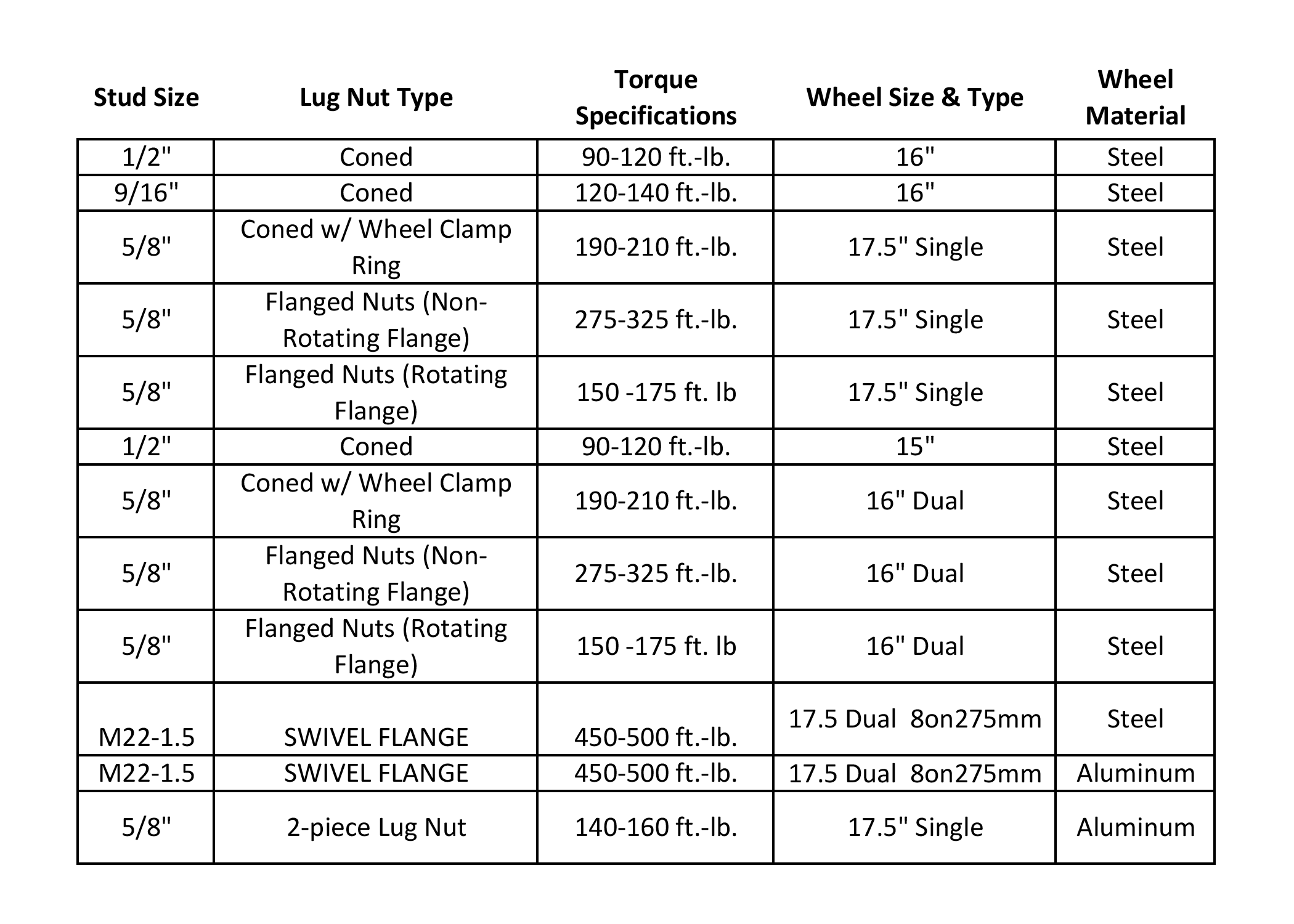

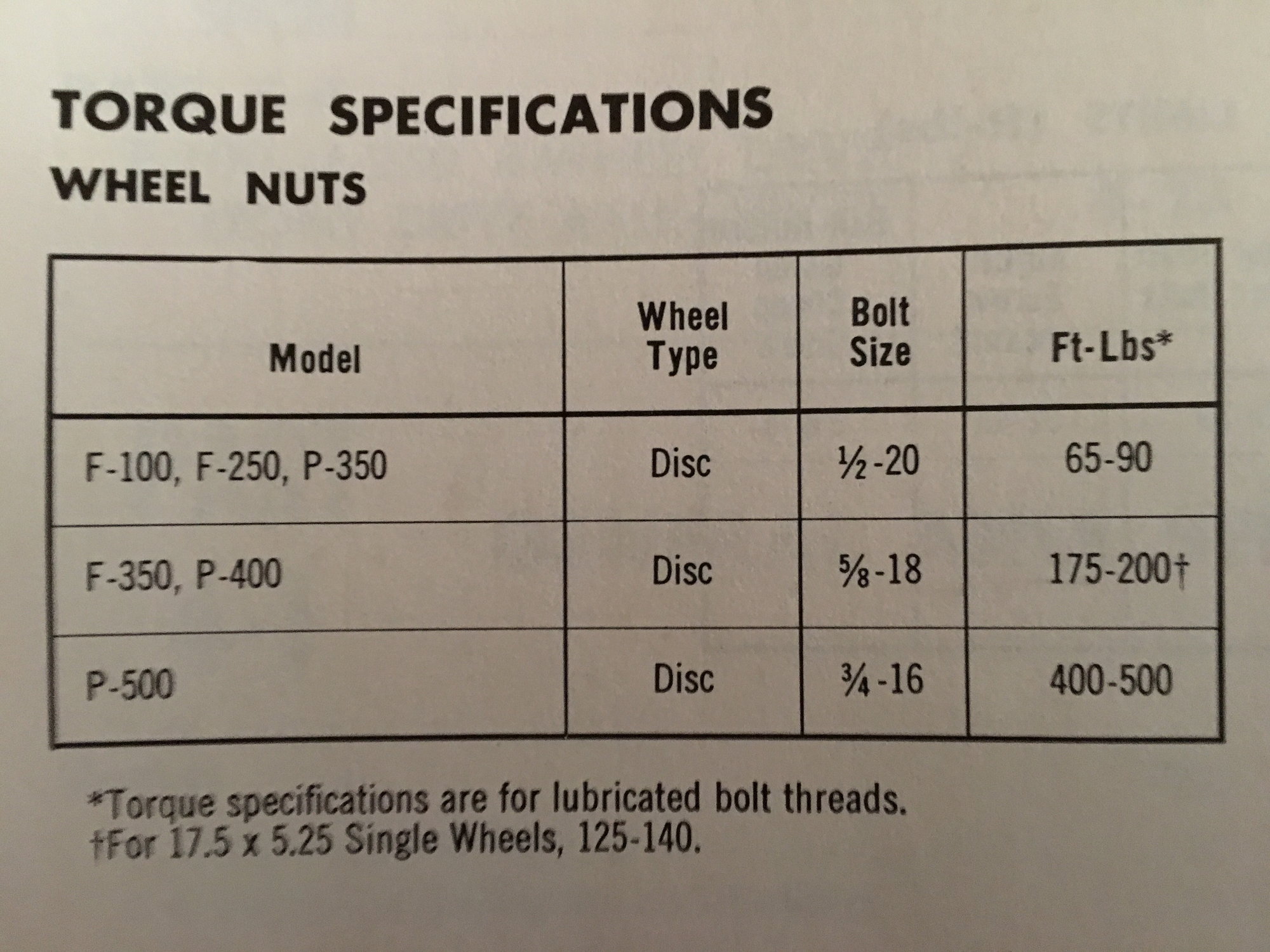

2025 Wheel Torque Chart Elahe Jasmine

https://support.karavantrailers.com/hc/article_attachments/6326542225171/Suggested_Torque_Specs.png

Torque has been converted into ft lbs by dividing the result of the formula by 12 All calculations are for Coarse Thread Series UNC Grade 2 calculations only cover fasteners 1 4 3 4 in Failure of the drive system to develop the recommended torque Tapped hole in soft material die casting Insert in plastic Over spin of power screw driver Size Stress Area Sq Inches Clamp

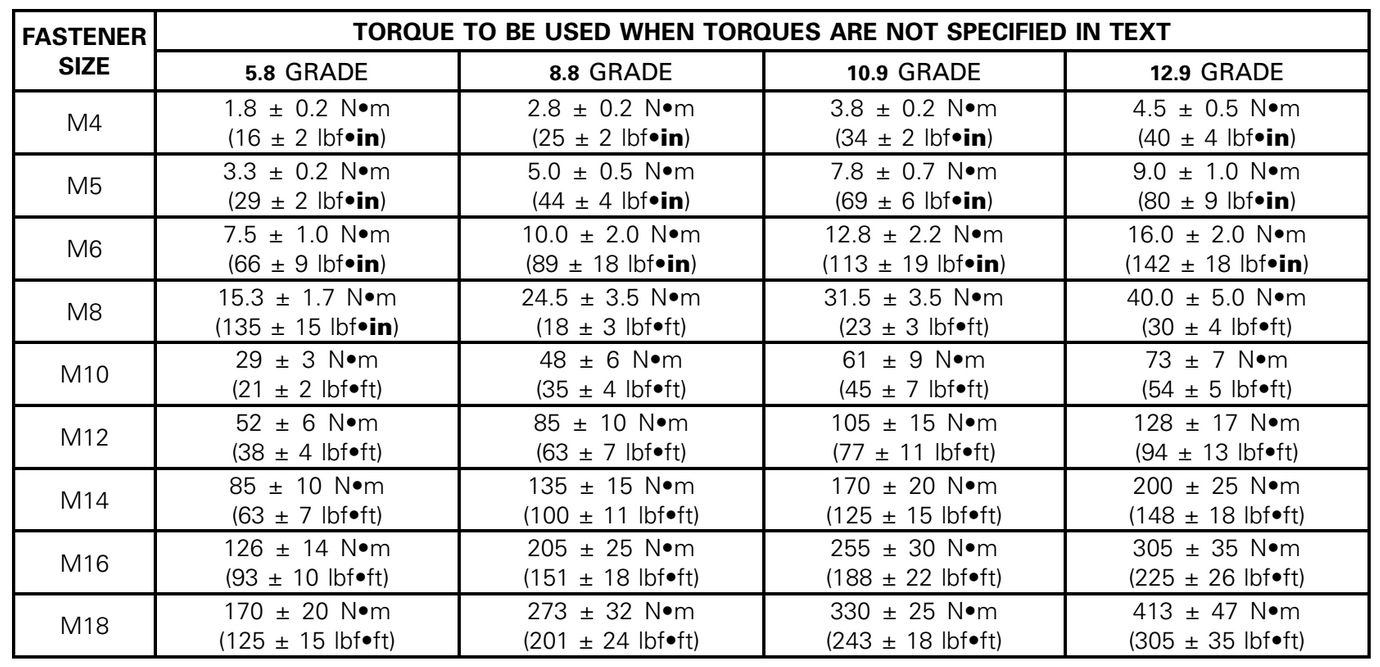

Recommended fastening torque ANSI Standard 2 56 4 40 6 32 8 32 10 24 10 32 1 4 20 PEEK 0 31 0 75 1 50 2 74 The charts below show the ideal tightening torque for each bolt grade for a variety of sizes The size column also includes the thread count Identify the grade size and thread density of your

Tundra U Bolt Torque Spec

https://alquilercastilloshinchables.info/wp-content/uploads/2020/05/Metric-Bolt-Torque-Spec-Chart-di-2020-Dengan-gambar.jpg

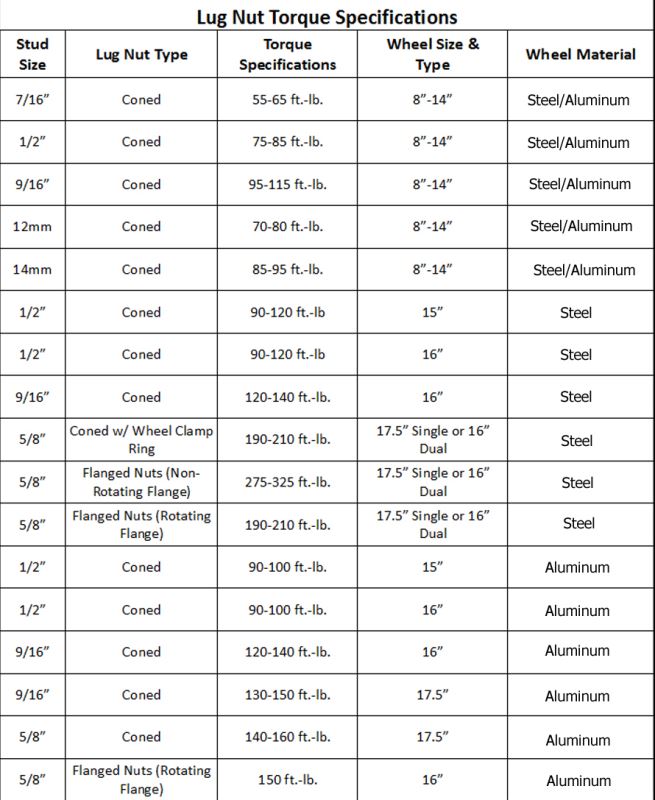

Lug Nut Specs Torque

https://www.etrailer.com/static/images/pics/q/u/qu117462_800.jpg

https://www.fastenal.com › content › feds › pdf › Torque …

Suggested Maximum Torquing Values a guide based upon actual lab testing on dry or near dry fasteners wiped clean While Fastenal has used reliable sources and testing to determine

https://shuntool.com › article

When working with 4 40 socket head screws in machinery it is recommended to aim for a torque setting between 65 70 of the failure torque rate This value will depend on

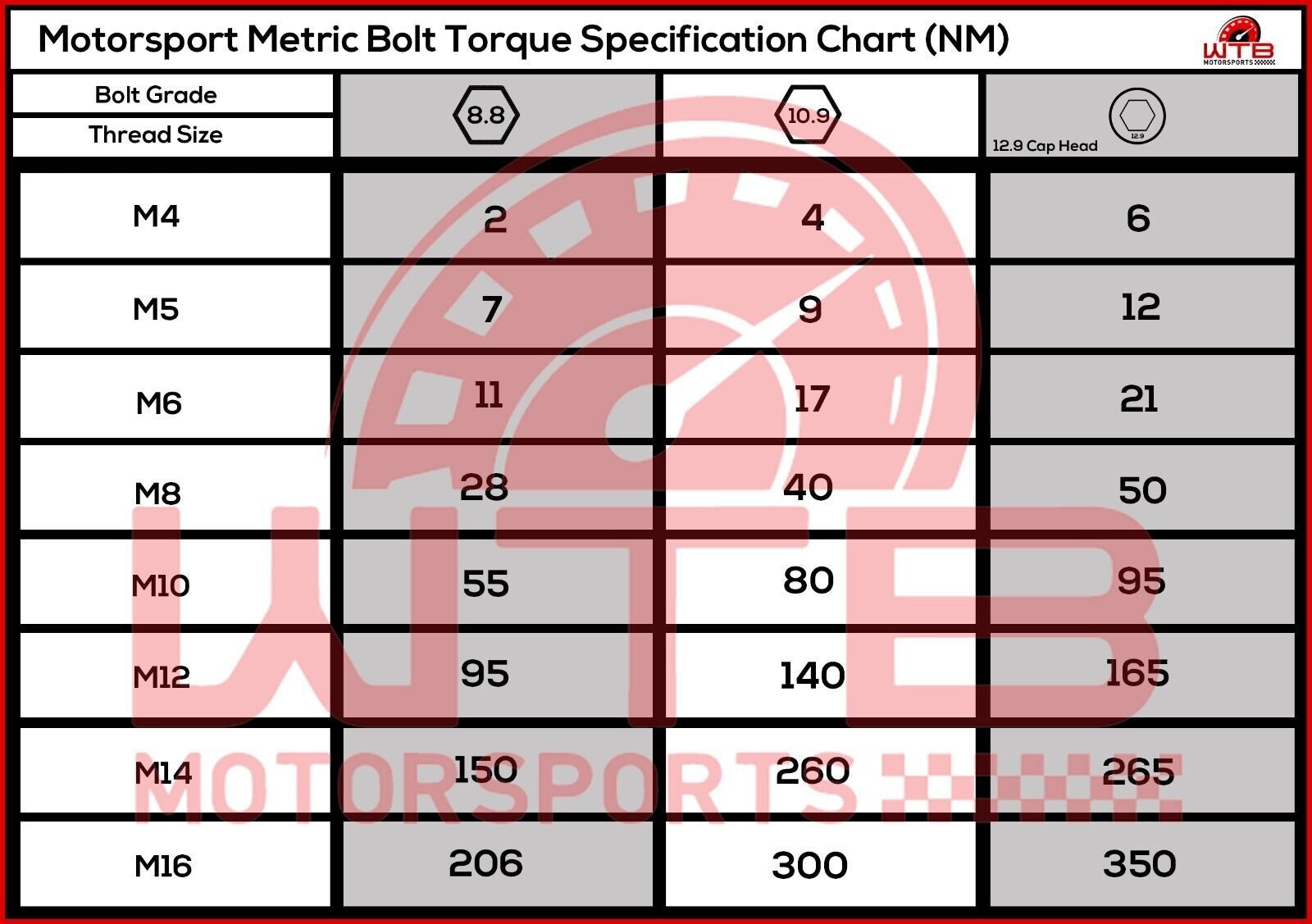

Motorsport Metric Bolt Torque Specification Chart WTB Motorsports

Tundra U Bolt Torque Spec

Wheel Lug Nut Torque Chart

Tire Torque Specs Chart

Polaris Ranger Wheel Nut Torque

General Torque Spec Chart

General Torque Spec Chart

Average Lug Nut Torque

Proper Spark Plug Torque

Specs 2017 Mustang Gt

4 40 Torque Spec - 4 40 UNC Basic Thread Dimensions Pitch minor major diameters depth lead Tolerance range for all applicable classes and much more